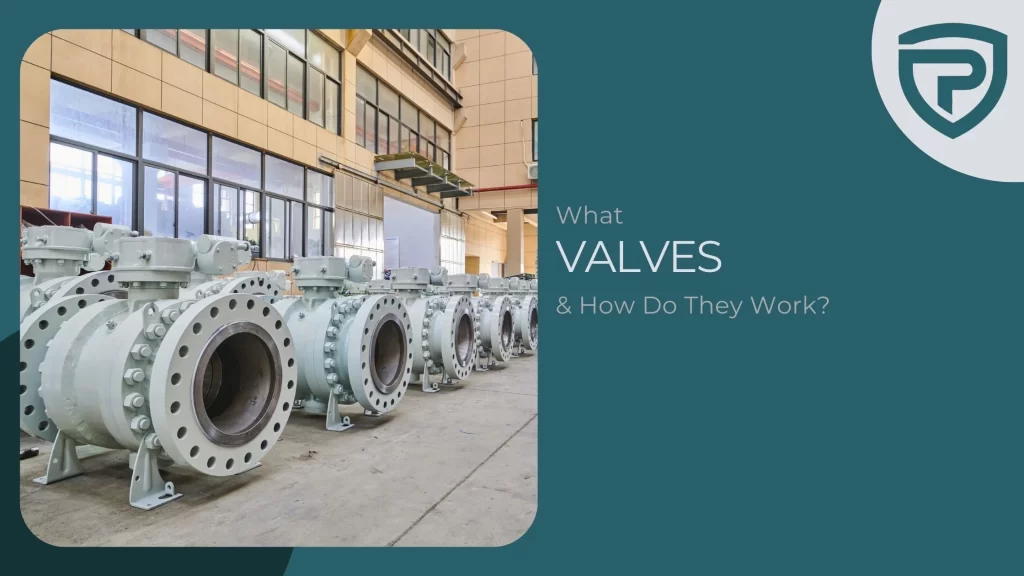

Valves are integral components in industrial systems that regulate the flow of liquids, gases, and even solids. These mechanical devices ensure safety, precision, and efficiency across various industries, including manufacturing, oil and gas, food processing, and water management. Choosing the correct valve for specific industrial needs can drastically improve operational performance and reduce system downtime. Likewise, sourcing valves from a reliable valve supplier like Permik Industrial ensures high quality, durability, and unmatched expertise.

This blog provides an overview of the most common types of valves, explains how they work, and highlights their practical uses in industrial applications whether you’re optimizing an existing system or planning a new one, understanding valve functionality can help you make informed decisions.

Let’s see other details to see how about valves problems and types.

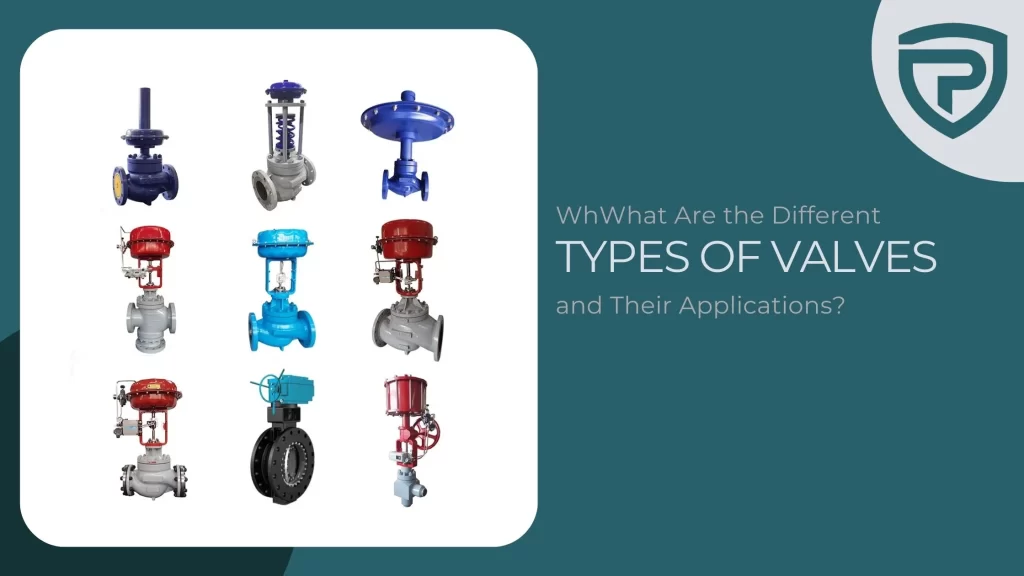

Common Types of Valves and Their Features

Ball Valves

How They Work:

Ball valves operate using a sphere with a hollow center (the ball) positioned inside a pipe. The ball rotates, controlled by a lever or handle, allowing the flow of liquid or gas when aligned with the pipeline. A simple turn of 90 degrees stops or resumes the flow, offering quick functionality.

Applications:

Ball valves are widely used in applications that require fast shutoff. They are ideal for oil and gas pipelines, municipal water systems, and chemical processing plants. Their precision and reliability make them suitable for both high-pressure and low-pressure environments.

Advantages:

- Low-pressure drop

- Excellent sealing capabilities

- Reliable for both on/off and controlled flow

Butterfly Valves

How They Work:

A butterfly valve uses a rotating disk mounted in the center of a pipe. When the handle is turned, the disk swivels to either allow or block the flow of fluids. The compact design makes it a lightweight option for large-diameter pipes.

Applications:

Butterfly valves are commonly found in water distribution, HVAC systems, and food processing lines. Their quick operation and small size make them ideal for tight spaces and fast-response environments.

Advantages:

- Cost-effective for large pipes

- Compact and lightweight

- Suitable for low-pressure systems

Gate Valves

How They Work:

Gate valves have a flat or wedge-shaped barrier (the “gate”) that can be lowered or raised to control fluid flow. They are designed for full-stop or full-flow situations, making them ideal for open-shut applications.

Applications:

Gate valves are typically used in water supply systems, oil pipelines, and wastewater management. They are also well-suited for high-pressure and high-temperature environments.

Advantages:

- Minimal flow resistance when open

- Reliable for isolation applications

- Durable for high-pressure uses

Note: While gate valves are excellent for on/off applications, they are not recommended for throttling as they may cause turbulence and wear.

Globe Valves

How They Work:

Globe valves regulate flow by utilizing a movable disk or plug that seals against a stationary ring. By adjusting the threaded handle, users can control the precise amount of fluid or gas passing through the valve.

Applications:

Globe valves are commonly used in cooling water, fuel oil, and turbine lubricant applications. They are also effective for throttling and flow regulation.

Advantages:

- Accurate and reliable flow control

- Durable and versatile for different media

- Can handle pressure drops effectively

Check Valves

How They Work:

Check valves are unique because they allow fluid to flow in only one direction. If the flow reverses, the valve closes automatically, preventing backflow in piping systems.

Applications:

These valves are frequently used in water pumps, steam systems, and process piping to maintain unidirectional flow and minimize contamination risks.

Advantages:

- Prevents contamination and backflow

- Low maintenance due to self-actuating design

- Works efficiently in automated systems

Pressure Relief Valves

How They Work:

Pressure relief valves automatically release excess pressure to prevent equipment damage or failure. They are triA preset pressure threshold triggers themes:

Pressure relief valves are widely used in boilers, tanks, and chemical processing plants. They ensure safety in high-pressure systems.

Advantages:

- Enhances safety by relieving excess pressure

- Keeps systems within safe operational limits

- Reliable and easy to install

Choosing the Right Valve for Industrial Applications

With so many types of valves to choose from, selecting the right one for your application requires careful consideration of several factors:

- System Requirements: Understand the specific needs of your system, such as temperature, pressure, and the type of media (liquid, gas, or solid) being transported.

- Valve Size and Design: Ensure the valve size fits your pipeline dimensions and that the design offers the desired operation, such as isolation, one-way flow, or pressure regulation.

- Material Compatibility: Match valve materials with the fluids or gases being handled. For example, corrosive gases may require stainless steel or plastic valves for long-term performance.

- Operational Needs: Determine if your system requires manual, automatic, or remotely controlled valves.

- Durability and Maintenance: Look for valves that are easy to maintain and built to last, especially in harsh industrial environments.

Working with a trusted industrial valves supplier like Permik Industrial ensures you can find tailored solutions for your specific requirements. Their expertise in providing high-quality products helps industries optimize performance and improve safety.

Industries That Rely on Industrial Valves

Valves play a critical role across numerous industries, supporting a wide range of applications:

- Oil and Gas: Controlling pressure in pipelines and preventing leaks.

- Water and Wastewater Treatment: Regulating supply, preventing backflows, and isolating pipes for repair.

- Chemical Processing: Managing aggressive and corrosive fluids at varying temperatures.

- Power Generation: Ensuring the smooth operation of heat exchangers, cooling cycles, and steam systems.

- Food and Beverage: Safeguarding sanitation while controlling liquids in production.

Different industries require different valve types based on operational demands, and the right supplier can make all the difference in ensuring efficiency and safety.

The Importance of a Reliable Valve Supplier

A high-quality valve is only as good as the supplier behind it. Partnering with the right industrial valves by a supplier ensures:

- Product Quality: High-grade materials and superior manufacturing mean fewer replacements and better performance.

- Expert Guidance: Professional suppliers like Permik Industrial can recommend suitable valve types for your industry needs.

- Compliance: Trusted suppliers guarantee products that meet strict industry standards and compliance regulations.

- After-Sales Support: A reliable supplier offers ongoing maintenance advice, troubleshooting, and quick replacements when needed.

At Permik Industrial, we pride ourselves on being more than just a valve supplier. We partner in your success, ensuring every solution is optimized for your operations. Learn more about the basics of valves in our blog, What Are Valves & How Do They Work?

Final Thoughts

Valves may be small components, but their importance in industrial operations is monumental. Selecting the correct types of valves for your system impacts efficiency and safeguards your equipment and processes. From ball valves in oil pipelines to pressure relief valves in boilers, each has a unique function that supports seamless operations across industries.

Whether you want to upgrade your system or start a new project, choosing a trusted valve supplier like Permik Industrial can make all the difference. With decades of experience, we’re here to help you find the right solutions for your industrial challenges.

Contact Permik Industrial Supply Company today to discuss your requirements and enhance your operations with premium industrial valves!