Industrial valves regulate fluid flow across multiple industries, including oil and gas, chemical processing, power generation, and water treatment. Selecting the right valve requires careful evaluation of various factors to ensure efficiency, safety, and longevity. Whether working with a valve supplier for the first time or looking to replace existing valves, understanding key selection criteria will help you make informed decisions.

Industrial valves regulate fluid flow across multiple industries, including oil and gas, chemical processing, power generation, and water treatment. Selecting the correct valve requires careful evaluation of various factors to ensure efficiency, safety, and longevity.

These mechanical devices control the flow, pressure, and direction of fluids or gases within a pipeline system. Depending on the industry, valves may be subjected to extreme temperatures, high-pressure environments, and corrosive materials, making choosing high-quality options from a trusted industrial valve supplier crucial.

Six Critical Factors to Consider When Choosing Industrial Valves Supplier

When considering What Are Valves & How Do They Work? Here is an answer. Valves actively control the flow of liquids and gases in various ways. With so many options available, it’s important to keep an eye on all the factors to ensure you select the correct valve for your application. Here are some of the most prominent ones.

Operating Conditions

The operating environment significantly impacts the choice of valves. Consider factors such as:

- Valves must withstand extreme heat or cold without failing.

- Choose a valve rated for the specific pressure range of your application.

- Ensure the valve allows sufficient flow without excessive pressure drops.

- Some valves handle corrosive, abrasive, or viscous media better than others.

Selecting a severe service valve (SSV) is crucial for industries dealing with severe conditions. These valves are designed for high cycling, extreme temperatures, and toxic materials and offer superior performance compared to General-Purpose Valves (GPVs).

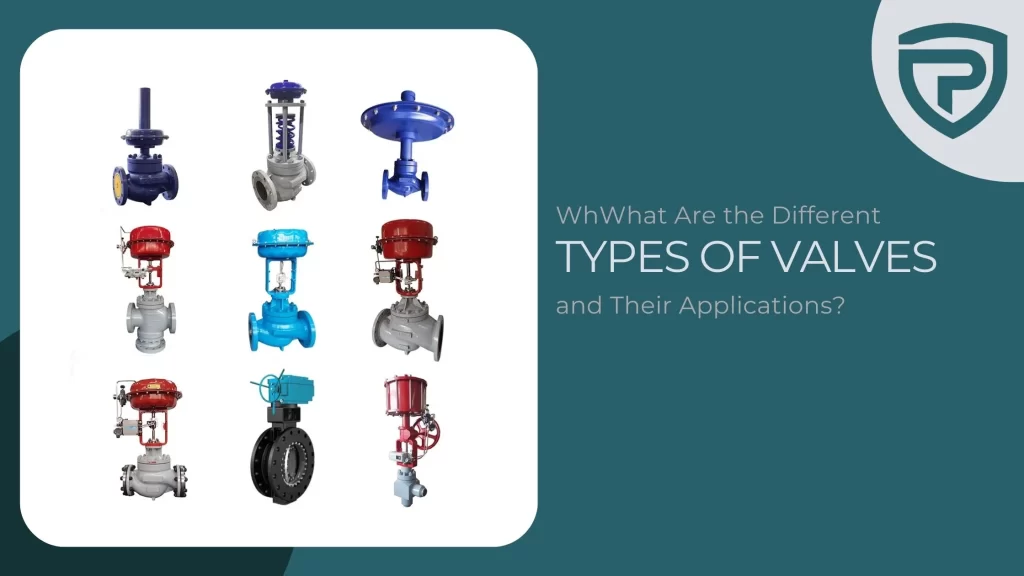

Valve Type and Functionality

Industrial applications require different types of valves based on their function. Understanding their roles helps in making an informed decision:

- Ball Valves are ideal for quick shut-off with minimal leakage.

- Gate Valves are best for on/off control in high-pressure environments.

- Globe Valves are more effective for throttling and flow regulation.

- Check Valves to prevent backflow and maintain unidirectional flow.

- Butterfly Valves are more space-saving and efficient for flow isolation.

Material Selection

The different types of valves and their Application determine their durability and performance. Some commonly used materials include:

- Stainless steel is highly corrosion-resistant and ideal for the chemical and food industries.

- Carbon steel is strong, durable, and suitable for high-pressure applications.

- Brass & Bronze are most commonly used in water and gas pipelines.

- Plastic (PVC, CPVC, PTFE) is lightweight, chemical-resistant, and used in low-pressure applications.

Material selection should be based on the valve’s chemical compatibility, temperature tolerance, and pressure handling capacity.

Valve Actuation Mechanism

Industrial valves can be operated manually or automatically. Understanding actuation types helps in selecting the best option:

- Manual Valves are operated using a handwheel or lever.

- Pneumatic Valves use compressed air for fast operation.

- Electric Valves are suitable for automated systems with remote control.

- Hydraulic Valves provide high force in applications like heavy machinery.

For complex systems, automated valves improve operational efficiency and reduce human intervention.

Sealing and Leakage Prevention

Leakage in industrial systems can lead to environmental hazards, product loss, and operational inefficiencies. When choosing valves, consider:

- Some industries require valves with absolute zero leakage.

- Soft-seated valves provide tight seals but may degrade over time, while metal-seated valves are more durable in extreme conditions.

- Ensure high-quality sealing components to prevent leaks over time.

Explore Different Types of Valves and Their Applications for more insights on choosing high-performance valves.

Cost vs. Long-Term Value

While initial valve costs may be a key consideration, it’s essential to assess the total cost of ownership (TCO), including:

- Some valves require frequent servicing, leading to higher operational expenses.

- High-quality valves minimize pressure losses and optimize system performance.

- Investing in premium-grade valves reduces downtime and replacement costs.

Businesses must evaluate whether they can afford frequent shutdowns for valve replacements or should invest in high-performance industrial valves that ensure uninterrupted operations.

Industries That Require High-Quality Industrial Valves

Many sectors rely on reliable Valves supplier partnerships to maintain efficient and safe operations. Some key industries include:

- Oil & Gas: High-pressure and high-temperature applications demand durable, explosion-proof valves.

- Chemical Processing: Requires corrosion-resistant valves for handling aggressive chemicals.

- Power Generation: Needs valves that withstand high thermal cycling and steam pressure.

- Water Treatment: Involves valves for flow control and filtration systems.

- Pharmaceutical & Food Processing: Requires sanitary valves with FDA-compliant materials.

Here is an answer to the question: Which Industries Need High-Quality Valves? If you are running, consider all the factors and choose one that suits your needs best.

Conclusion

Partnering with a reliable valve supplier ensures access to high-quality products that meet your operational requirements. Industries can improve efficiency, minimize downtime, and enhance system performance by focusing on these critical factors.

For expert guidance on valve selection and procurement, consult a trusted supplier or visit a reputable industrial supply company like Permik Industrial. We provide top-quality industrial valves that meet the highest performance and durability standards. Our team is committed to helping businesses find the perfect solutions for their operational needs.

Contact us today, and let us help you optimize your operations with the right industrial valves!